Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

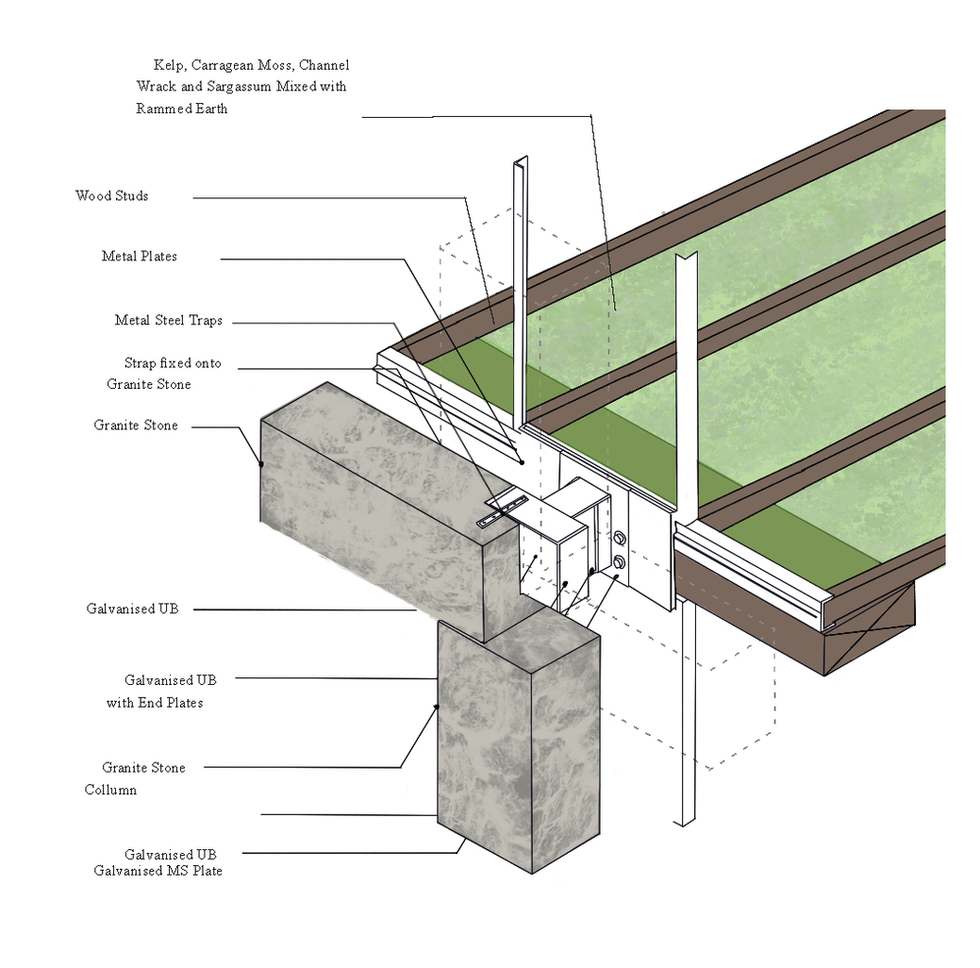

Seaweed Research Quarters

Project Type

Sustainable Design, Educational, Public and Private

Date

June 2024

Location

Roosevelt, Connemara,

Galway, Ireland

This project is about how this site will be a research facility to test and help understand seaweed and how it can help with construction materials, creating a cheaper and more sustainable way to grow and how these materials can be used across different industries like food, beauty and building. There are other inspirations for this project from the vernacular architecture around the area, what materials in abundance are available and how I could use them in a sustainable way.

Granite, Clay, Hay, Seashells, Seaweed which can be used with traditional techniques into creating a new building.

Seaweed is right in front of the site and it grows in abundance throughout the year. I investigated different ways that these could be harvested and maybe even use as a construction material.

These themes explore the way I saw these spaces and how I could change the perception of light, materiality, texture and how time can affect the way buildings are affected.

This project aims to learn, investigate and find a way of contributing to the communities around the site.

Ireland has been a country that supports its communities and counties. Everyday life has become easier for these communities as the Irish government is working closely with the State’s Heritage to protect the Irish culture, land, ocean and of course, Architecture.

Galway’s County is part of this program and it is been actively trying to help protect building’s and saving their history.

This project is based on the west coast of the country, in the Galway county, in Connemara. The Coastal Guard Station is located right in front of the Pacific Ocean. Around the site there are 2 Shellfish Companies and Mungo’s Small Business based into products made out of seaweed, abalone, sea cucumber and sea urchins.

A licence under the 1933 Foreshore Act is not required by the holder of that right in order to harvest seaweed, nor can any other entity be licenced under the Foreshore Act to harvest seaweed in an area where existing formal or informal rights to harvest seaweed already exist.

Regime under the Foreshore Act 1933 (as amended), managing a range of different marine activities and infrastructural developments. Section 3 of the Act provides for the granting of a licence for the removal of or the disturbance of beach material on the Foreshore.

Active aquaculturalists: These are individuals with licensed sites for seaweed culture, individuals involved in aquaculture (abalone farmers) who wish to start seaweed culture to feed farmed abalone and urchins; and (2) processors:- individuals who are involved in processing wild seaweed for the food sector.

Harvesting Methods

Foraging

Foraging is the practice of harvesting foods from the wild. In general only a small group of people engage in this activity, and the impact is minimal, with only what is required being taken.

Scoubidou

Developed in the 1960’s the Scoubidou is a curved iron hook mounted on a hydraulic arm and rotated. During this process the kelp is uprooted and pulled aboard a dredger. Approximately 2 tonnes can be harvested per day (based on one boat).

Mechanical harvesting

It is claimed that mechanical harvesting is required as there is a decline in the number of young people willing to “engage in such dirty work”. However, with fewer people to employ and the economics of scale, the main reason may be more economic than social. The following mechanical methods are currently known to be in other countries, and similar methods would be employed in Ireland.

Cutting Dredge

Based on the Norway Dredge; A 3m long iron sledge with forks pointing towards the drag direction is pulled along the seabed by a trawler designed for seaweed harvesting. In theory the trawl cuts plants larger than 20cm from the substrate, leaving smaller plants for re-growth. The trawl pulls up to 1 ton of kelp per drag and up to 150 tons daily.

(M. Meland, C. Rebours 2012). However video uploaded to Youtube shows the dredge pulling up entire plants, including the attached substrate (Craftmank 2011).

Suction Cutter

Kelp plants are pulled into a cutter via suction. The seaweed is then cut, and further suction transports the seaweed into the harvesting boat. The depth of the cutter is set and controlled by sonar, some also have underwater cameras.

Drying Seaweed Methods

Sun drying (SD): wet biomass was incubated directly under the sun for 48 hours in a location that allows the

maximum of illumination hours

Air drying (AD): biomass was covered with 4 layers of aluminum and incubated at room temperature for 48 hours